A NOVEL METHOD FOR MAKING MINIATURE LENSES

By Alvaro Amaro de Azevedo - May 2007 (pdf)

Re-published in html Jan. 2014

|

|

Introduction

The process to be described below could well be regarded as a good example of “Darwinian evolution” through natural selection. From its humble origin to this presently evolved form, a chain of evolutionary changes was set in motion by an interminable sequence of trial and error assays, each causing unforeseen mutations. Features that made it better have survived and those which did not, underwent extinction. The surviving product of this evolution was “the fittest”

for use. Therefore, despite the technique may look an intelligent method, it wasn’t a fruit of “intelligent design”.

|

|

|

|

Nr. |

Other Materials |

|

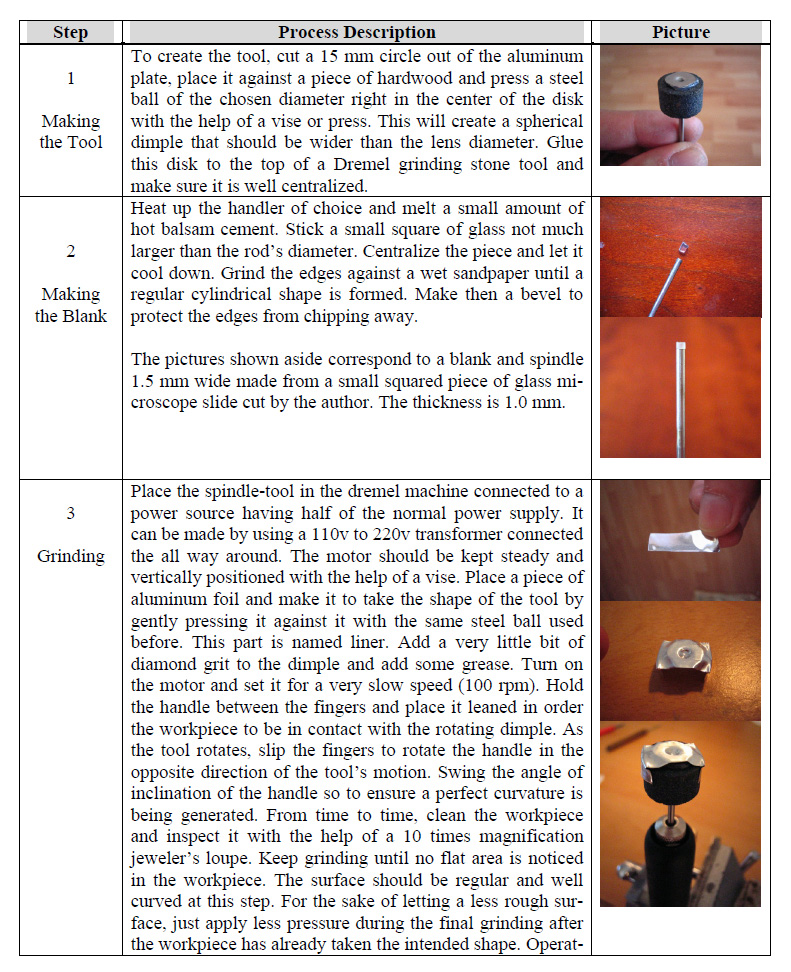

1 |

Aluminum plate 1.0 mm thick |

|

2 |

Vaseline grease |

|

3 |

Glass cutting tool |

|

4 |

Sand paper 80 grit and 220 grit and/or diamond file |

|

5 |

Various sizes of steel balls from different ball bearings |

|

6 |

Hot Glue stick |

|

|

|

|

Final Notes and Conclusion |

|

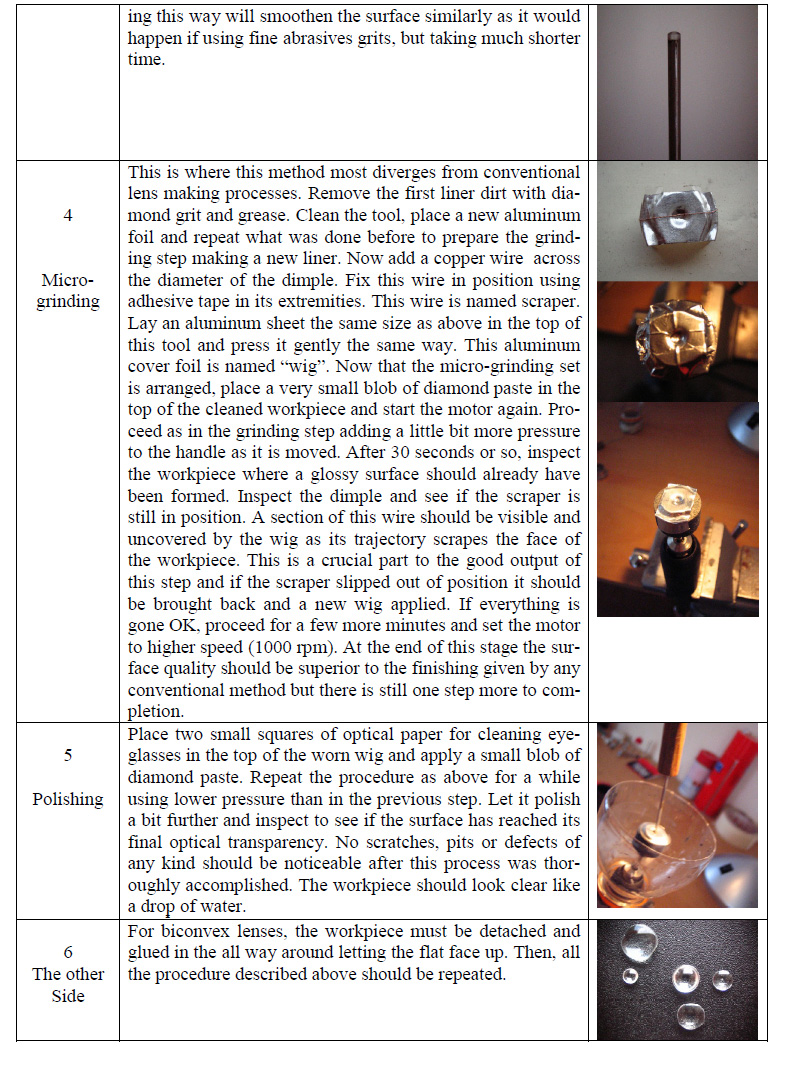

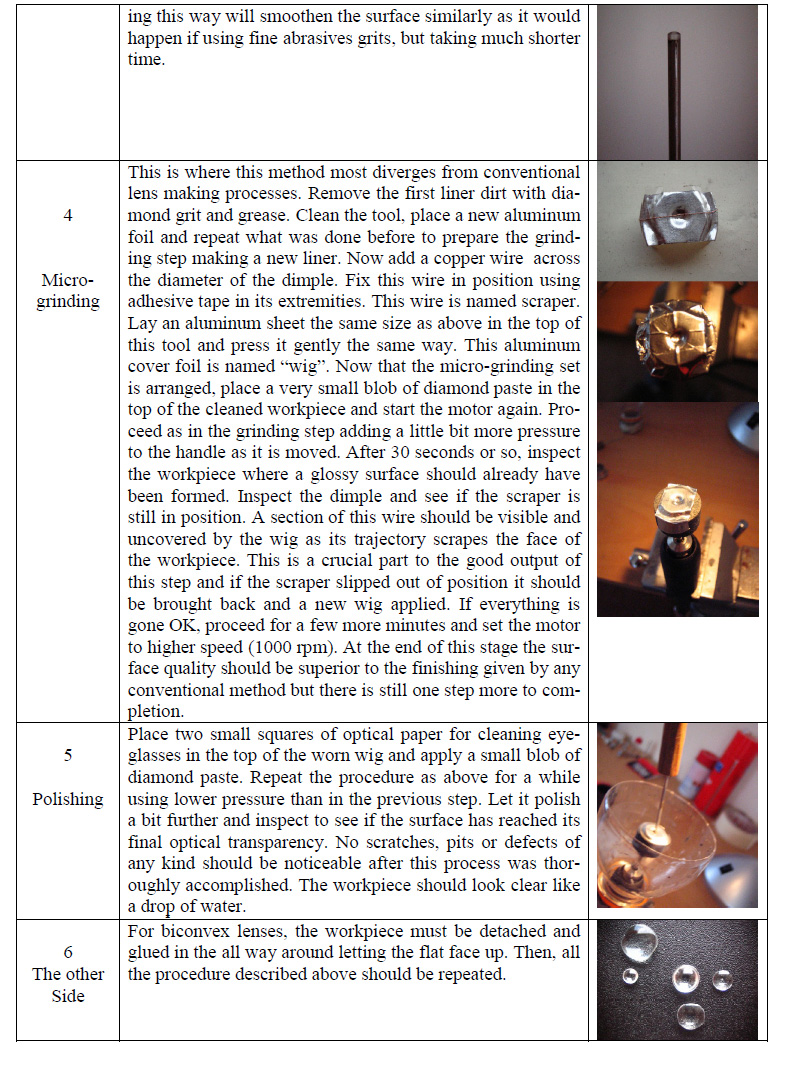

As for any handcraftsmanship or hobby, this method also requires repetition and persistence in order to be fully mastered, but is far simpler to be learned than its “pre-Cambrian” ancestor. Using liners, will make the tools last virtually forever so one can make a set of tools with different curvature radii and be able to generate a wide variety of lens profiles. The liners however are disposable and should not be used more than once or twice. When

the edges persist

to stay rougher than the center, the solution is to add more layers of aluminum sheet to the top of the wig and proceed polishing. This will extend the polishing action to the imperfect edges of the lens. The home brewed cement used by this author was made by combining 80% Brazilian Cherry tree resin with 20% bee’s wax. This resin is taken from Hymenaea courbaril which is similar to

the temperate climate copal resin. Given the quantities used in each lens making process and since there is no waste, the diamond paste from a 5g syringe should last for a life time, so as the diamond grit. Cutting small glass squares may be not as easy as it looks like. One can also shatter a small piece of plane glass and choose a chard that suits best but this will require taking all necessary safety precautions to prevent injuries these chards may inflict if improperly handled. The motion of the scraper seems

to subject the workpiece to a micro-grinding action in which material is removed under ductile regime. It’s known that ductile abrasion can remove material without creating micro-cracks. Because polishing would solely smoothen the sharp edges left behind during coarse grinding, the underneath layers with a network of microscopic cracks cannot be eliminated. This causes the surface to reach a high degree of smoothness and shiny appearance but not to be highly transparent. Micro-grinding however, can obliterate

the roughened outside layers and keeping removing underneath cracked strata formed during the brittle regime of coarse grinding until all damaged layers have been removed. Conventional lens making techniques can eventually led to surfaces of very high quality, but it will require a lengthy and painstaking process consuming considerable time. The presence of unremoved micro-cracks will ultimately scatter light lowering the quality of the image and overall performance of the lens. The simple introduction of a material

removal under ductile regime using the scraper can suppress the undesired layers at a fraction of that time. The evidence that supports this claim lies in images observed from a bright punctual light source. Lenses made by other techniques show foggy and halo surrounded images, while those made by this ultimate method show minimum if any halo at all. One notices nearly no flare and highly contrasting crispy sharp images of subjects under transmission light observation, feature that hasn’t been possible previously

with ordinary lens making method. |

"Man has always to be busy with his thoughts if anything is to be accomplished." Antony van Leeuwenhoek (1632 – 1723)

* The last paragraph reflects the author’s own interpretation of the phenomenon based on his understanding of the existing knowledge and systematical observations not representing a definitive description. This note should be seen as a personal view rather than as a statement.

|

|

© Microscopy UK or their

contributors.

Please report any Web problems or offer general comments

to the

Micscape

Editor

.

Micscape is the on-line monthly magazine of the Microscopy

UK website at

Microscopy-UK

.

©

Onview.net Ltd, Microscopy-UK, and all contributors 1995

onwards. All rights reserved.

Main site is at

www.microscopy-uk.org.uk . Re-Published

in the Jan 2015 edition of Micscape

Magazine.

|