| Measuring NA of the microscope condenser | |||||||||||||||||||||||||||||||||||||||||

| using DIY thick plate glass Apertometer | |||||||||||||||||||||||||||||||||||||||||

| By Dushan Grujich, on February 2nd. 2013 | |||||||||||||||||||||||||||||||||||||||||

| At one time or another we all gather various optics for our 'scopes that we are uncertain of their parameters hence we are unsure how to use them to our best advantage. Myself, not being an exception to the rule, I have also acquired a number of different pieces. Among other things there are: Zeiss pancratic system condenser with top aplanatic NA 1,4 lens, LOMO OI-14 NA 1.4 aplanatic, three Abbe 1.2 NA two of them branded and one no name. | |||||||||||||||||||||||||||||||||||||||||

| Presumably one has desire to make sure that the valued possessions are what they claim to be. I have been curious wanting to compare condensers in order to find differences between them and to assess possible benefits that I could realise by using particular condenser rather than the other one. | |||||||||||||||||||||||||||||||||||||||||

| Instigated by successful experiment in measuring NA of objectives I ventured in an attempt to measure the NA of several condensers which I have. Again I faced a problem of the equipment to use for measuring the NA. While looking at Cheshire's Apertometer I have seen suggestion for making an apertometer using thick plate glass1. This looked feasible and easily achievable with means available at home. | |||||||||||||||||||||||||||||||||||||||||

| To make the apertometer one needs a slip of thick plate glass 40 x 75 mm (1-1/2" x 3") about 10 mm (~1/2") thick. One side should be frosted with carborundum or diamond paste as fine as possible, the other side should be left clear. At the centre of the clear side one should mount a piece of tin foil with the pin hole made in the centre under a cover slip. Detailed instructions are given in "The Microscope"1 pages 211-216 §266-§268. | |||||||||||||||||||||||||||||||||||||||||

| Application of the apertometer is simple. One places the glass slip with the pinhole on the bottom at the microscope's object stage, frosted side up. Next step is to place strong light illuminator, such as for dark field observation and then focus and centre the pinhole to provide homogenous circle of light on the frosted surface, taking care that the pinhole is at the condenser focus by adjusting the condenser height. Then we can measure the circle diameter and use it to calculate the NA. | |||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||

|

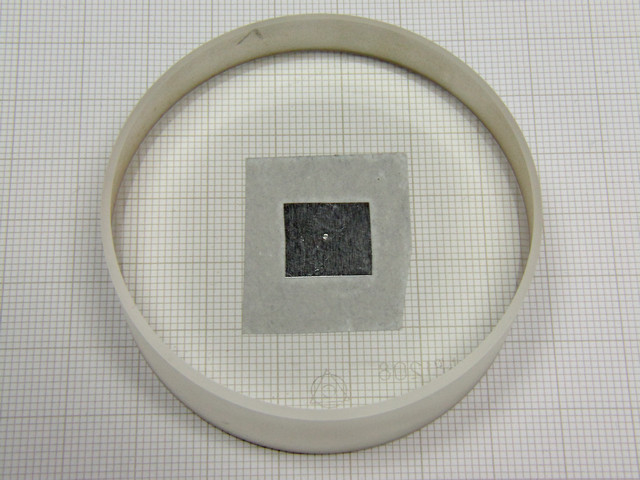

The Optical Flat shown with aluminium foil with a pinhole stuck to one side | |||||||||||||||||||||||||||||||||||||||||

| I have used one of my 60 mm (2-3/8") diameter, 20 mm thick Optical Flats made of clear optical glass type K8 with Refractive Index of 1.516373, one should know nD as it is required for accurate determination of condenser NA. Since I did not want to destroy the Optical Flat by frosting one of the surfaces I departed from instructions in following way: instead of frosting I used small piece of thin plastic drafting film laid on the top surface for taking the measurement, with the assumption that it shall not influence readings too much, expecting that it will not introduce too large an error as the measurements I was doing were dry anyway. | |||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||

|

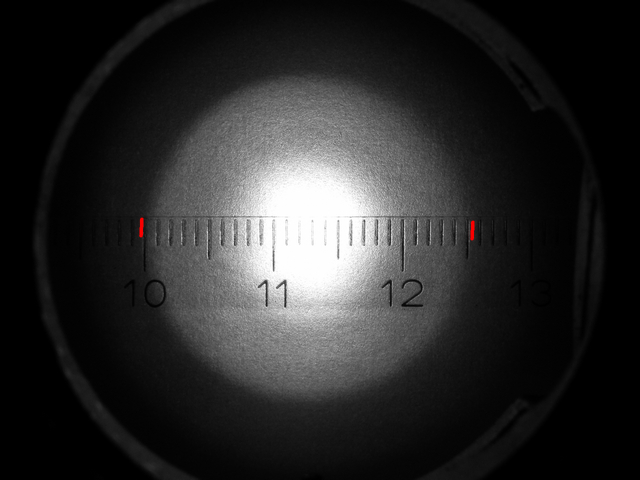

The image above shows the top surface of the glass plate, with light cone projecting on the frosted surface | |||||||||||||||||||||||||||||||||||||||||

|

Calculation of NA is straightforward, first we need to find angle u i.e. α/2 |

|||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||

| The results of my measurements did initially seem questionable as they vary considerably from the expected i.e. from the maximal theoretical results. The next thing for me to do was to consult relevant literature. The answer came from the Russian book "Optika Mikroskopov"2, on page 352 it is stated that the LOMO condenser KOH-3, when used dry, has the NA of 0.80, and when the top lens is removed and only the lower lens is used the NA of 0.30 with 27.0 mm distance of the lower surface of the glass slide to the top surface of the lower lens. Data from the book show that the condenser NA measurements which I have made are accurate or are very close to the factual. | |||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||

|

Conclusion with some of my thoughts regarding the use of immersion objectives with a condenser dry | |||||||||||||||||||||||||||||||||||||||||

| This prompts a question I have had in my mind about the use of immersion objectives with condenser dry. Students in most instances are not taught to oil the condenser and bridge the air gap, practice which I find is rather wide spread at schools and universities. What is the sense of buying and using quite expensive objectives with NA high above 1.00 if using condenser dry, knowing that the limiting factor is the air gap between condenser and glass slide which reduces the NA of the optical system to the theoretical maximum of 1.0 and apparently in some cases to a value substantially lower . | |||||||||||||||||||||||||||||||||||||||||

| Now, after I have measured the condenser NA and have witnessed how aplanatic condenser has NA reduced from 1.4 to ~ 0.90 if used dry, looking at an even worse situation of using an Abbe condenser with its NA reduced from 1.20 to 0.80 hugely increases my curiosity and makes me wonder about performance of condensers from other makers. | |||||||||||||||||||||||||||||||||||||||||

| All of this brings back to my mind statements about the routine work use of the condenser dry, like: | |||||||||||||||||||||||||||||||||||||||||

|

"§125. Correlation of objective and condenser aperture. It is evident from the experiment in 124 that if the objective is to be used at its full aperture the condenser on the microscope must be of sufficient aperture to satisfy the objective. Strange as it may appear, however, many microscopes are regularly supplied with objectives of 1.25 to 1.30 N.A., and much is made of the fact, but the condenser supplied on the microscope has at the outside not over 1.20 N.A. and not one in a hundred who

uses such a microscope ever makes immersion contact with the condenser and glass slip, and therefore never uses more than an aperture of 1.00 N.A. The few that would like to utilize the high aperture, of which so much is said in the microscope catalogues of all manufacturers, cannot do so with the low aperture condenser regularly supplied.

Fortunately it is now becoming the fashion of users of the microscope to know something of the optics of their most efficient servant and the manufacturers are helping to spread the knowledge needed, and to supply most excellent condensers to meet the most exacting requirements. It is to the credit of the British microscopists and manufacturers that they have always been in the lead in such matters. (See Brewster, Carpenter-Dallinger, Nelson, Coles, and Conrad Beck, etc.)"1 |

|||||||||||||||||||||||||||||||||||||||||

|

"Therefore, if the highest magnification objective is an oil immersion objective with a numerical aperture of 1.40, then the substage condenser should also have an equivalent numerical aperture to maintain the highest system resolution. In this case, immersion oil would have to be applied between the condenser top lens and the underside of the microscope slide to achieve the intended numerical aperture (1.40) and resolution. Failure to use oil will restrict the highest numerical aperture of the system to 1.0, the highest obtainable with air as the imaging medium."3 | |||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||

| "As we mentioned above, condensers with numerical apertures above 0.95 perform best when a drop of oil is applied to their upper lens in contact with the undersurface of the specimen slide. This ensures that oblique light rays emanating from the condenser are not reflected from underneath the slide, but are directed into the specimen. In practice, this can become tedious and is not commonly done in routine microscopy, but is essential when working at high resolutions and for accurate photomicrography using high-power (and numerical aperture) objectives."3 | |||||||||||||||||||||||||||||||||||||||||

| References: | |||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||

| Author's email: dushangrujich AT gmail DOT com | |||||||||||||||||||||||||||||||||||||||||

| Published in the July 2013 edition of Micscape Magazine. | |||||||||||||||||||||||||||||||||||||||||

| www.micscape.org | |||||||||||||||||||||||||||||||||||||||||