The Nikon Model S Microscope: Replacing the fine focus spur gear.

by T Rand Collins, Canada

Mirrored with permission from the author's blog (dated Feb. 9th 2016) Through the Lens: Microscopes and Other Equipment

on his website The Island Pond: Field notes on the aquatic life of Vancouver Island.

The Nikon Model S microscopes from the 1970s, with their quality all-metal construction, excellent craftsmanship and optics, shiny black finish, and multiplicity of options, are still some of the best general-purpose and research microscopes ever developed:

The Nikon Model S microscopes from the 1970s, with their quality all-metal construction, excellent craftsmanship and optics, shiny black finish, and multiplicity of options, are still some of the best general-purpose and research microscopes ever developed:

“…the black Nikon S scopes that were first released in the 1960s … are still hallmarks of versatility and quality and have developed a faithful following despite their age. The Nikon SBR was the first,

the Nikon Ske and Nikon Skt, were research grade microscopes, and the Nikon Lke with constant Köhler illumination and changeable nosepiece was the top of the line in its day. Nikon designed these scopes with many interchangeable components so that a scope could be customized to every application…”

(Courtesy Fred Durette, http://snakesafe.jalbum.net/)

The image (shown right) is of my own, recently-restored Nikon S-Kt. However, this wonderful line of microscopes suffered from one serious design flaw, ironically resulting from one of the few plastic (nylon) parts on this otherwise superbly-crafted instrument: the infamous Nikon S fine focus spur gear.

This nylon gear, used probably because it never needed lubricating, was constructed as a 107-tooth nylon ring surrounding an inner brass collar pressed onto an eccentrically-mounted steel ball bearing on the fine focus shaft. Since molded plastic materials were not as structurally sophisticated in the 1970s as they are today, with time this plastic ring contracted and broke, disabling the fine focus mechanism and causing thousands of service calls. Brass replacements for this gear could

be purchased as aftermarket parts for a number of years, but are almost completely unavailable today. Hundreds of otherwise excellent Model S microscopes have been shelved or broken up for parts for no reason other than this one defect. This problem is well known in microscopy circles.

I purchased this Model S-Kt scope with lenses on eBay for $75. It had not been used for 20 years and was advertised as “…not

turning on…” This problem was fixed in 10 minutes

by re-soldering a flange on the bulb, and, apart from some dirt on the knobs and a few paint chips and dust, and , the instrument was in beautiful shape. However, the fine focus mechanism moved unevenly, revealing a broken fine focus gear and a potentially serious problem.

Right. 1971

Nikon Model S with KT base, providing Köhler Illumination.

Changing The Model S Spur Gear

After a week of fruitless phone calls all over the United States, Bob Lair of ScopeDoc, a fellow member of the international Amateur Microscopy group, suggested that I contact an old associate, Mark Morris:

Mark Morris, Micro-Maintenance Inc.

2648 Simpson Circle, Duluth, Ga 30096

770 449-6896 (Fax 770 446-5761)

microscope@mindspring.com

www.microscope-maintenance.com

Mark, the only North American source for these gears, works with a machinist who hand manufactures replacement Nikon S brass spur gears, and had two remaining from the last lot – probably a significant fraction of the world’s remaining supply. With $50* and a few days’ patience, I had my gear. Replacing it turned out to be

a relatively simple process, as described below. Do NOT lose any of the irreplaceable small parts!

*Note added April 16th 2016 by the Micscape Editor. Thank you to Mark Morris who notes that the current batch price is $75.

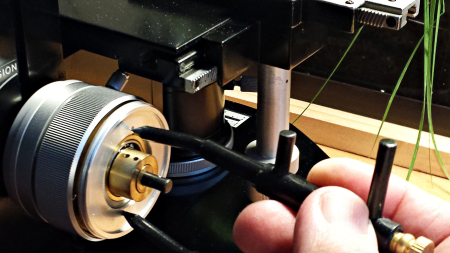

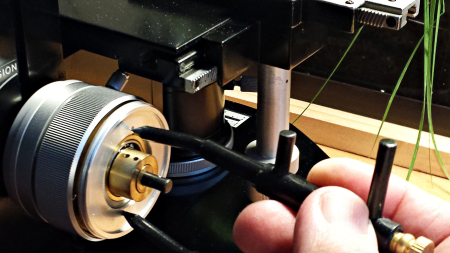

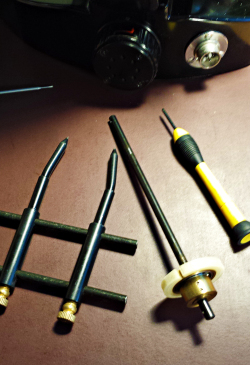

First, viewing the microscope from the back, remove the right fine focus knob by removing the single screw holding it onto the shaft. Then, using a specialized spanner inserted into the two small holes in the underlying cover (a lens wrench works well), unscrew the circular cover that forms the center of the larger coarse focus knob:

Removing the fine focus mechanism cover.

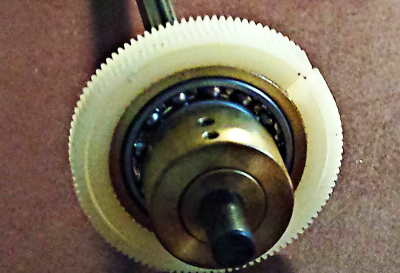

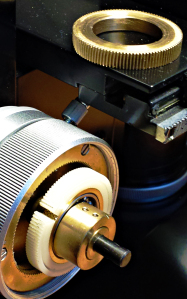

After the cover is removed, the spur gear is visible, with the crack appearing as a dark space in the white nylon gear:

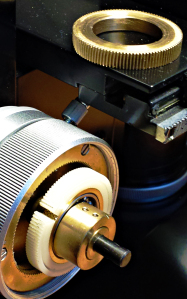

Cracked spur gear and brass replacement.

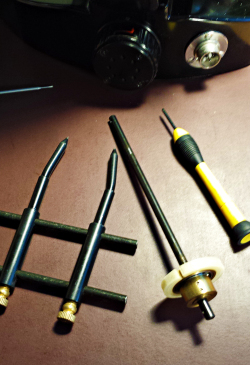

Then remove the left fine focus knob, being careful to retain in the proper order the two small washers beneath the knob:

Left side of fine focus shaft with two small washers.

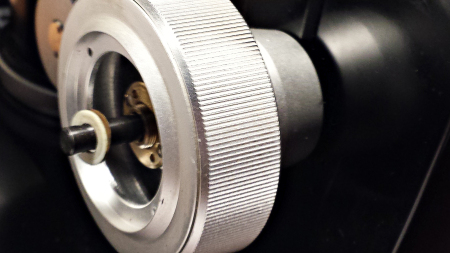

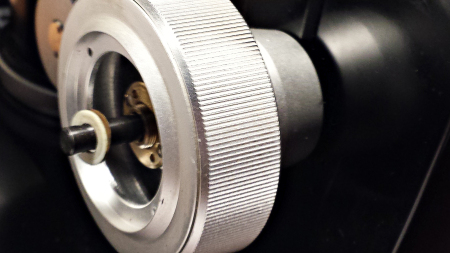

Once the left knob and washers are removed, the whole fine focus shaft and spur gear assembly should easily pull out from the right side:

Spur gear assembly.

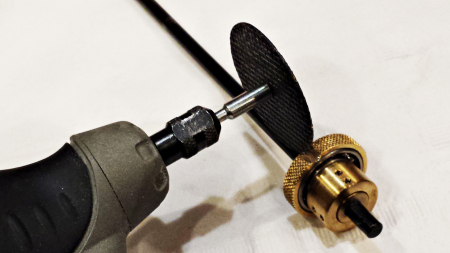

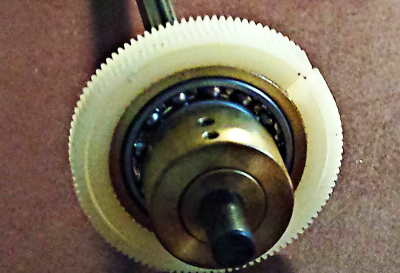

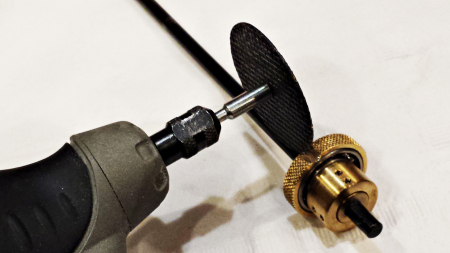

The toothed nylon gear should pull off easily, but this leaves the underlying brass collar that has been firmly pressed onto the eccentrically-mounted steel ball bearing. This can be cut off carefully with a small carborundum wheel mounted on a Dremel tool:

Cutting the brass inner collar of the spur gear.

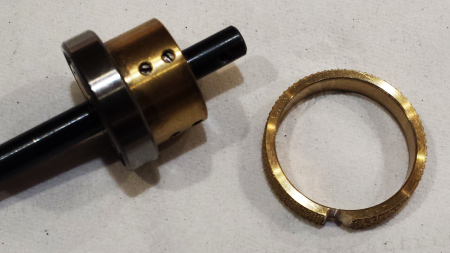

Cut carefully through this brass ring until only a thin bridge of brass remains, then crack the bridge

by inserting a screwdriver into the slot and twisting it. This protects the bearing from being cut by the grinding wheel. The collar can then be readily slid off:

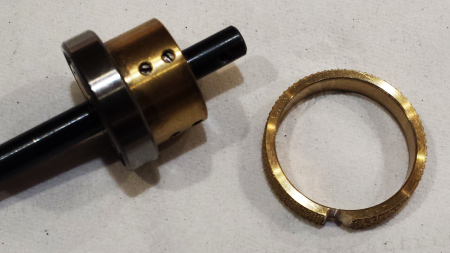

Spur gear collar after removal. Note the thin inner bridge of brass that has been cracked to remove the collar.

The final challenge is to press on the new brass gear. This can be done by one of three methods: Tapping the carefully-sized new cylindrical gear onto the bearing (recommended by Mark), using concentric rings to press or tap on the gear, or employing the thermal expansion method.

A combination method proved most effective. I cooled the bearing for an hour in the freezer, then heated the cylindrical

brass gear on a stove element until it

was just uncomfortably hot. Holding the gear with a tea towel, it could be pressed half way onto the cold bearing with firm finger pressure before temperatures equalized and it seized in place. This oriented the two pieces. I then placed the assembly flat on the edge of a counter and tapped the gear gently with a small hammer, rotating with each tap. This proved effective but slow, so I grasped the edges of the gear and bearing between the jaws of a pair of plumber’s pliers. Applying

gentle pressure at intervals around the gear and bearing, rotating the assembly between each gentle squeeze, quickly but gently pressed the gear onto the bearing and leveled the two surfaces. The gear proved to be very carefully machined and was easily guided to a smooth and precise fit.

The whole shaft and gear assembly was then carefully cleaned, lubricated with a sparse amount of grease, and reinserted into the scope. The washers, right cover, and knobs were quickly

replaced. The reassembled fine focusing mechanism now moved silkily, with absolutely no hesitation. The

finished scope.

Note: Original Nikon S System advertisement 1963 (Anal. Chem., 1963, 35, pp 91A–91A):

The Nikon Model S microscopes from the 1970s, with their quality all-metal construction, excellent craftsmanship and optics, shiny black finish, and multiplicity of options, are still some of the best general-purpose and research microscopes ever developed:

The Nikon Model S microscopes from the 1970s, with their quality all-metal construction, excellent craftsmanship and optics, shiny black finish, and multiplicity of options, are still some of the best general-purpose and research microscopes ever developed: