and Step-by-Step Sample Preparation

Ulf Griesmann, Gaithersburg, Maryland, USA

Bone is an educational

and rewarding subject for the amateur microscopist. In this

article I describe the preparation of bone samples for optical

transmission microscopy and illustrate the remarkable

observations that can be made with rather modest means. The

preparation methods described here may also be of interest to

students and their teachers who want to take a closer look at

one of the most astonishing, and astonishingly complex,

natural materials. The first part of this article describes

the preparation and mounting of bone thin sections. In

the second part, several micrographs are discussed that

were made using a simple LOMO Multiscope microscope (known as

Biolam outside the US).

Bone is opaque and must be prepared in the form of thin

sections for the brightfield transmission microscopes that are

most readily available to amateur microscopists or in

educational settings. One advantage for the amateur is that

the preparation of bone specimens does not require the use of

dangerous chemicals for fixing and staining, because most

features can be observed without elaborate specimen

preparation. Without a saw microtome, making thin sections is

tedious work, but the procedure described in the following

paragraphs yields sections that allow for surprisingly good

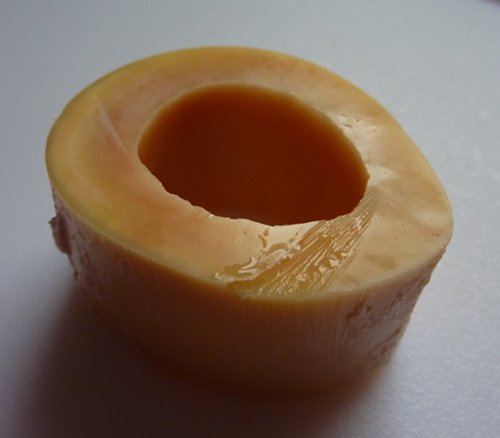

images. Fig. 1 shows a piece of bovine (cow) long

bone, about one inch in length, that was cut from a fresh leg

bone with a saw. The bone section was cleaned with warm water.

Figure 1: About one

inch (25 mm) long section of bovine long bone.

A complete imaging of the complex

three-dimensional structure of bone requires multiple

transverse, longitudinal, and radial sections. Here I will

concentrate on the preparation of a transverse bone

section. The finished bone section will be bonded to a

microscope slide and so the first step is to grind flat

and polish the part of the bone that will be glued to the

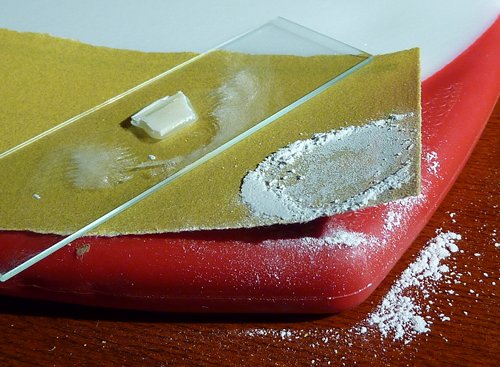

slide. This grinding step is illustrated in Fig. 2. The

grinding is done using emerald paper from a DIY market

where paper with grit sizes down to 600 is commonly

available. Further polishing was done using a set of Micro-Mesh polishing

pads (shown in Fig. 3) for wood polishing with up to 12000

grit, which achieve a mirror-like finish. The samples can

be prepared either wet or dry, but it is much easier to

bond a wet sample to the microscope slide because suitable

water compatible glues, e.g. surgical glues, tend to be

very expensive. The bottom side of the bone does not have

to be finished all the way to a mirror finish because it

will not be viewed with the microscope, but it should be

fine ground without large, visible scratches.

Figure 2: Grinding

the "bottom" of the bone sample.

Figure 3:

Micro-Mesh polishing pads used for bone polishing.

Figure 4: Bone slice with one fine-ground side.

Once the bone piece has been ground to

a fine finish, the piece is clamped in a vise and,

using a small hacksaw, a slice as narrow as possible

is cut from the bone as is shown in Fig. 4. Next,

the bone slice, like the one in Fig. 4, is cut up

into about 5 mm x 5 mm chips which are bonded to

microscope slides using a clear epoxy glue. Fig. 5

shows two chips, one a transverse section, the other

a longitudinal section, being clamped to microscope

slides while the epoxy glue cures. The clamping is

important to make sure the glue layer between slide

and bone chip becomes as thin as possible. Fig. 6

shows the result - a bone chip that is about 1 mm

thick bonded to a microscope slide. Wet samples can

be glued with acrylic superglue, which is somewhat

water compatible because the curing reaction is

catalyzed by water, but the result is a bond that is

much more fragile than the epoxy bond and much less

likely to survive the subsequent grinding and

polishing. Most of the ones I tried peeled off

during grinding. Bone chips that are kept for later

glueing can be stored in isopropanol if they are

destined to become dry samples or de-ionized water

in case they will remain wet. Purists can use

physiological saline solution or Ringer's

solution to temporarily store wet samples.

Figure 5:

Bone chips being glued to microscope slides.

Figure 6: A 5

mm x 5 mm x 1 mm bone chip bonded to a microscope

slide.

The bone sample

must now be ground and polished to a thickness

between 25 µm and 30 µm. If the bone

section becomes too thin there will be nothing

left to look at; if it is too thick, the

structures near the surface will be confounded

by features that are buried inside the section.

The thin grinding is the most difficult part of

the sample preparation and it will require some

practice. Holding the slide between thumb and

middle finger and supporting the back with the

index finger, the thickness of the sample can

quickly be reduced by grinding with emerald

paper as is shown in Fig. 7. People with

allergies or concerns about, heaven forbid, mad

cow disease may want to wear a face mask when

preparing dry sections to avoid inhaling bone

dust. At this stage it is easy to get bored and

grind too fast; it is better to go slow than to

start over. The thickness of the section must be

monitored with a micrometer as is shown in Fig.

8. Once the thickness drops below about 200

µm a finer grit must be used for a while

and then the next finer grit and so on. The

purpose of the polishing is to remove the

scratches and the damage that is introduced in

the sample by the larger grit abrasives. As the

section thins, the grit size should be reduced

until a 25 µm thick section is obtained

that is polishded to a mirror finish with the

finest available grit. A successfully polished

section looks like the one shown in Fig. 9.

Finally, the polished section is wiped clean

with isopropanol or water and the section is

mounted under a coverglass. Dry sections can be

mounted with Mount-Quick (Daido Sangyo Co. Japan) or a similar medium, wet

sections may be mounted in glycerin gelatin.

(For wet mounted sections, the edges of the

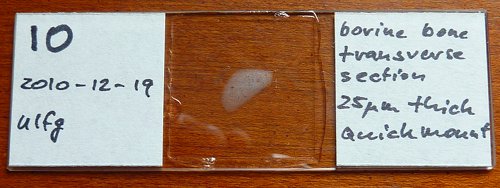

coverglass must be sealed with varnish.) Fig. 10

shows a finished slide. A 25 µm thick

section still appears noticeable opaque. Wet

sections mounted in glycerin gelatin will become

more transparent over time because glycerin is a

clearing agent for bone.

Figure 7:

Grinding of a thin bone section.

Figure 8:

Measuring the bone section thickness with a

micrometer.

Figure 9:

A finished thin section.

Figure

10: A finished slide with cover glass and

labels.

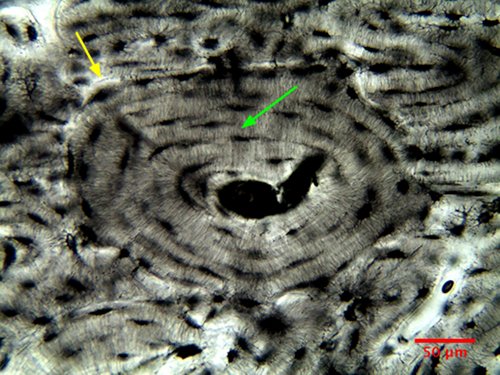

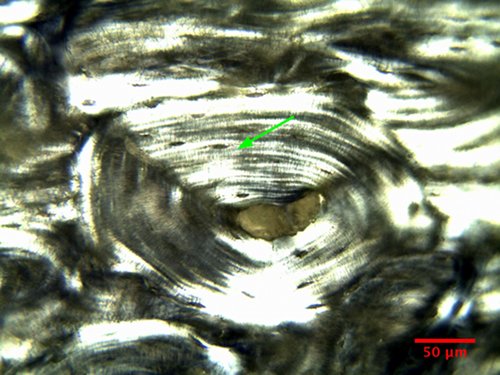

With

slides finished it is time to look at them

under the microscope! Figs. 11 - 15 are made

with my modest LOMO Multiscope microscope

that is fitted with a Motic 3 megapixel

camera. Fig. 11 is a beautiful picture of

the fundamental structural feature of

compact bone - an osteon. Osteons are bone

columns made from concentric layers, or

lamellas (lamellae). The green arrow

in Fig. 11 points to one of the lamellas. At

the center of each osteon is a conduit,

called a Haversian canal, that carries

vessels for the blood and lymph supply. The

outer boundary of an osteon is the cement

line (actually a sheet) pointed to by a

yellow arrow in Fig. 11. The Haversian

canals at the centers of osteons are

connected in a ladder rung-like fashion by

canals that are called Volkmann's canals.

In Fig. 11, a Volkmann canal can be seen

branching off to the right from the central

Haversian canal.

Figure

11: Osteon in a transverse section of bovine

long bone (20x, NA=0.65).

Everywhere along boundaries

between lamellae in Fig. 11 are small voids

that are more clearly seen at larger

magnification in Fig. 12. The voids are called

lacunas, or lacunae in high falutin (related

to the words "lake" and "lagoon"). They are

about 10 µm long and 4 µm wide.

Some of the lacunae can be seen as dark

shadows in Fig. 12 because they are buried

beneath the surface of the bone slice. Each of

the lacunae is home to a bone building cell

called osteoblast.

These cells have laid down a bone lamella

until they became imprisoned in the bone that

they have created. Their connection to the

outside is a vast network of small channels, or canaliculi, which can be seen in Fig. 12

connecting the lacunae within an osteon.

Canaliculi do not cross the cement line.

Figure

12: Lacuae and canaliculi in bovine osteon

(oil immersion, 60x, NA=1).

When the

light that enters the condenser is polarized

by placing a polarizer in the filter holder

and a second, crossed polarizer at the image

plane of the microscope objective, the

sub-structure of the bone lamellas becomes

visible. Fig. 13 is the osteon of Fig.11 but

imaged with polarized light. The green

arrows in Figs. 11 and 13 point to the same

location. The lamellas appear to have a

sub-structure made of layers that respond

differently to polarized light, which

implies that the structure and organization of the bone in these layers must be

different.

Figure

13: Bovine bone osteon in polarized

illumination (20x, NA=0.65).

A

particularly beautiful find is Fig. 14,

which shows an example of bone remodeling

and the creation of a new osteon. In a

living animal, bone is constantly modified

by carefully orchestrated processes of

disassembly and rebuilding. Bone is

dismantled by specialized cells, called osteoclasts, which

dig tunnels into the bone and release the

molecular building materials into the blood

stream. The bone tunnels are then populated

by osteoblasts

that build new osteons from the outside in.

The balance of these two processes

determines if the bone in a specific bone

area is strengthened or weakened. In Fig. 14

the beginning of a new osteon in the space

left behind by the activity of an osteoclast

is captured and the first lamellas that have

been laid down as part of the new osteon can

be discerned.

Figure

14: Bovine bone remodeling (20x, NA=0.65).

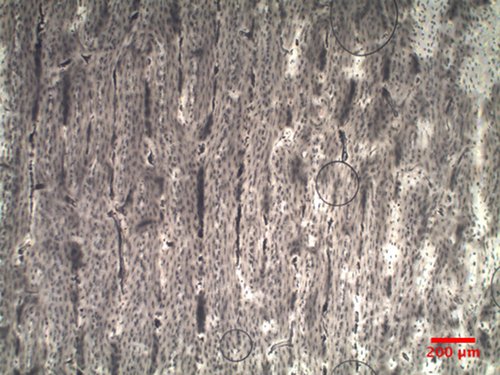

Finally, Fig. 15 is a lower

resolution image of a longitudinal section of

bonvine bone. The column structure of the

osteons in this part of long bone are clearly

visible - as are some amateurish bubbles in the mounting medium.

Figure

15: Bovine bone, longitudinal section (4x,

NA=0.12).

Figs. 11 to

15 are merely a glimpse of the complexity of

bone. A real slide is like a strange

country that awaits discovery and I hope

that some of the readers are inspired to

make their own bone thin sections and study

them with their microscopes. Higher

resolution versions of the bone images are

available for download. Readers

with an academic bent can go to their

library to learn more about bone and how it

functions. The famous book by Bruce Alberts

et al. "Molecular

Biology of the Cell", Garland Science, would be a good start.

All

comments to the author are welcomed.

Microscopy

UK Front Page

Micscape Magazine

Article Library

© Microscopy UK or their contributors.

Published in the

May 2012 edition of Micscape.

Please report any Web

problems or

offer general comments to the Micscape

Editor.

Micscape is the on-line monthly

magazine

of the Microscopy UK web

site at Microscopy-UK

© Onview.net Ltd, Microscopy-UK, and all contributors 1995 onwards. All rights reserved. Main site is at www.microscopy-uk.org.uk.