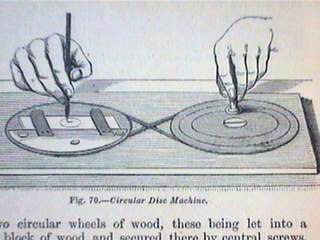

Slide-ringing tables were made in Europe and the U.S. during the 19th and beginning of the 20th centuries. The earliest form was a contraption made of two wooden disks with their edges grooved to take a cord. They were fixed to a board with a screw in the centre of each disk and the disks placed at a short distance from each other in a linear fashion. The cord loop was then placed in the groove of the first disk, crossed, then put into the groove of the second. One of the disks had a wooden handle affixed near its periphery, this was used to drive both disks via the drive-cord. The second disk had clips with which to hold the slide while ringing or other preparations were made. (See diagram below).

(See footnote 1 for

image source).

A metal form was later developed which made things much

easier, one of which was given to me by Dr. Manuel del Cerro,

editor of the Journal of the Microscope Historical Society,

New York (see footnote 2). I cleaned it slightly to remove

the years of dirt and dust only to find it was once

nickel-plated as evidenced by the small patches still

adhering to the brass table. The cleaning operation also

revealed the hidden signature on the table: E.H. Griffith,

Pat. Ap'd for, Fairport, N.Y. (No, this is not a spelling

mistake on my part, the abbreviation 'app'd 'is actually

written with one 'p' on the table).

Detail of signature

I discovered from information given by Mr. Mike Dingley of

Australia that Ezra Griffith worked at Fairport during the

period 1875 to 1890 and was only awarded the patent in Dec.

1886 which dates this table before the award as it has Pat.

Ap'd. for on it. In comparison to most existing tables this

one has many additional resources. There are the usual

concentric rings used as an aid to centering the coverslip on

the slide, plus the usual slide clips, but what makes this

one different is the fact it has a 'stop' pin which positions

the slide so its centre coincides with the central point of

the table (the pin is removable by unscrewing). The aligning

of the slide is also aided by two removable pins screwed into

the central revolving part of the table, these can also be

used to lock the slide and ensure its correct position. One

of the slide clips is affixed to a screwed pin which is

itself screwed into the periphery of a small round brass disk

which rotates, this can be locked in any position via a

thumb-screw under the table. The table also has a large,

comfortable, square hand-rest which attaches to the rear body

of the table by hooked extensions to two metal pins located

on each side of the latter.

|

|

Underside of the table

Why use a slide-ringing

table at all? What are the benefits? Can they still be

purchased? The answer to the first question is; using such a

table permits all of the work to be done in a small area and

the coverslip placed in the correct position on the slide.

The answer to the second is your slides look professionally

finished and gives an appealing look to your work, besides

sealing the object onto the slide which does not permit

solvent to evaporate from the preparation. It also prohibits

fungi and humidity from entering between slide and cover thus

spoiling your work. Your slides will last much longer if

ringed correctly.

Examples of the author's own prepared slides

Making dry mounts is made that much easier too; simply make a

ring of gold size or asphalt varnish a little smaller than

the cover to be used for the mount. When the varnish is

'tacky', place the cover over the ring and lightly press the

ring into position so the varnish forms a seal. When the

varnish is dry you can ring normally to seal your slide. This

also works very well for objects mounted in fluids other than

resins. You can cut circular covers from rectangular ones

using the table and a diamond tipped pen. You can even make

several sizes of simple dark-field 'stops' with the table

using black paint.

Another interesting use is when objects must be placed on a dark background for incident lighting effects, such as is used for mounting foraminifera. This is effected by making a black spot to the required size using matt black paint and leaving to dry, then place your object in the center of the spot and mount dry as described above.

And lastly, yes, fortunately slide-ringing tables may still be had from e.g. from Brunel Microscopes (UK). They have the usual concentric rings to aid in centering the cover and a rest/aid for the ringing-brush. Asphalt-based varnish was used some time ago but is difficult to find, although Northern Biological Supplies (UK) still stock and sell this as well as goldsize (see link above). I use synthetic acrylic paint; it does the same job and looks identical to the varnish, simply because the asphalt product isn't available in this part of the world. However one can obtain an asphalt based varnish here which never really sets absolutely hard, I use this to make the sealing rings for my dry mounts before ringing.

Comments to the author

Roland Mortimer roland@imagelink.com.br welcomed.

(If

your web browser isn't set-up for e-mailing by clicking the

above, just highlight and copy the address into your standard

e-mail software).

Footnotes:

1) The drawing of the old ringing table was sourced from Jabez Hogg's "The Microscope, its

History, Construction and Applications", fourth edition,

1859, publisher Routledge Warnes & Routledge (London).

2) Details of the Microscope Historical Society and contact/membership details which have been kindly supplied by Manuel del Cerro are here.