By Andrew Entwistle

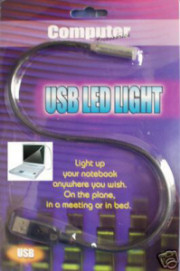

Fig. 1 An inexpensive LED cold light based upon USB powered flexible lights

Introduction

By Andrew Entwistle

Fig. 1 An inexpensive LED cold light based upon USB powered flexible lights

Introduction

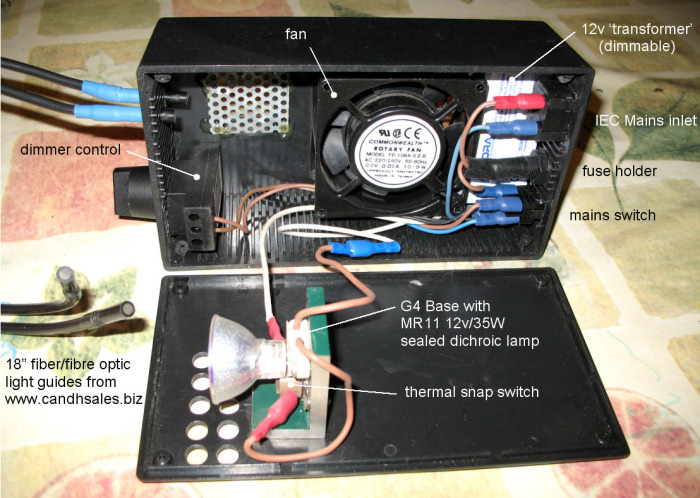

Fig. 2 Tungsten halogen fibre optic cold light. A dimmer control is used in conjunction with a low voltage lighting ‘transformer’ (actually a switched mode power supply) to drive the lamp via a temperature trip, in case of fan failure.

Modification of the USB LED light

Fig. 3 A USB flexible LED light, available for £1 from ‘pound shops’ and for around £4 inc. P&P from eBay (May 06)

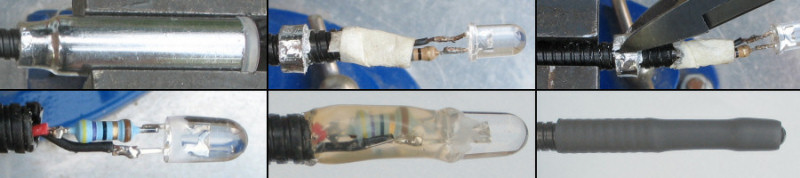

Referring to fig. 4 the stages of modification are as follows.

Fig. 4 The stages in modifying the LED light to have a slimmer profile and possibly an alternative LED

Refer to figures 5 & 6. A rectangular hole was made at each end of the enclosure so that two USB type A PCB mounting sockets could be glued securely to the side walls of the enclosure with two part epoxy. The inside surface of the box was scored with a knife to provide a good key for the epoxy. The USB LED lights were plugged into the sockets before gluing, to reduce the amount of glue entering the connector, and to hold it in place. It took a degree of force to remove the USB LED light connector after gluing and some trimming of the excess glue inside the socket was required to allow the plugs to connect and disconnect smoothly. A 4xAA battery holder was used to hold four NiMH rechargeable cells which were wired to the USB sockets in series with switches. The connections to the type A USB sockets are shown in figure 6. With the weight of the batteries the base is just about stable enough to support the two USB lights in any orientation, but I added a 10mm thick aluminium plate underneath the enclosure to improve the stability. The bottom of the plastic enclosure was glued to the aluminium plate, which was drilled and tapped to accept two knurled headed screws to enable tool-free battery changes. Four self-adhesive rubber feet were applied to the base of the plate.

Fig. 5 USB type A socket (viewed from mating side).

Fig. 6 The layout of the internal components

Results using flexible gooseneck LED lighting

Fig. 7 LED illumination used with a stereo microscope

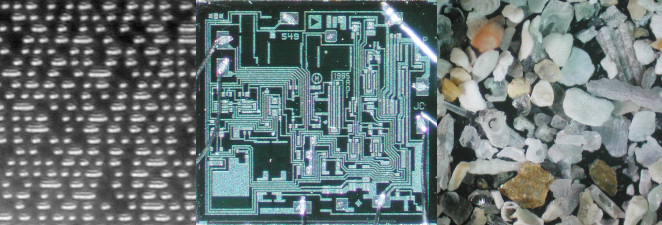

Fig. 8 The pits of a CD viewed through a 40x objective, an

AD549 OP-AMP die and a foram strew through a 2.5X

objective.

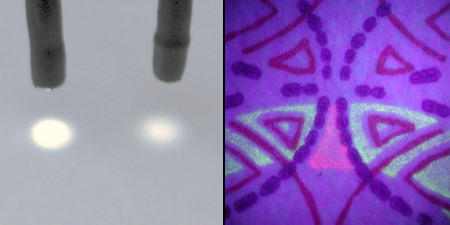

Fig. 9 Comparison of 25000mCd white LED (left) with 8000mCd LED & flourescence of £20 note printing under 395nm near-UV illumination.

All comments to the author Andrew Entwistle are welcomed.

Microscopy UK Front Page

Micscape Magazine

Article Library

Please report any Web problems or offer general comments to the Micscape Editor .

Micscape is the on-line monthly magazine of the Microscopy UK website at Microscopy-UK